Smashlaps

A helmet-mounted product designed to let you know if you're beating your last downhill bike run

Smashlaps along for the ride at Rancho Penasquitos, San Diego.

Smashlaps uses red, yellow, and green LEDs to let you know if you're beating your best/recent/friend's time down a downhill biking trail.

The unit uses Bluetooth Low Energy to connect to the Smashlap app. The app lets you set start and end points on a map. After defining the start and end points of a trail, the light on the unit turns green when you're beating your previous time, yellow when you're lagging by 2 seconds or less, and red when you're farther behind.

The beauty of the Smashlap is that you don't need to look at it to read a display or see the light. Just let your brain process the contents of your peripheral vision and you'll know whether you're beating your last run (or average run speed) without taking your eyes off the trail.

Smashlaps will be available in a beta release late June 2018. The 2018 downhill season will be limited to Android systems only; the iOS app will make use of lessons learned in the beta program and is scheduled for release in early 2019.

Smashlaps makes use of Kroova's electronics design resources, 3d printers, pick and place machine, reflow oven, and prototyping shop.

Smashlaps uses a neat mixed-signal micro FPGA to handle button presses and power management

Electronics design

Smashlaps was a great opportunity to dive into some low power electronics and medium-scale production.

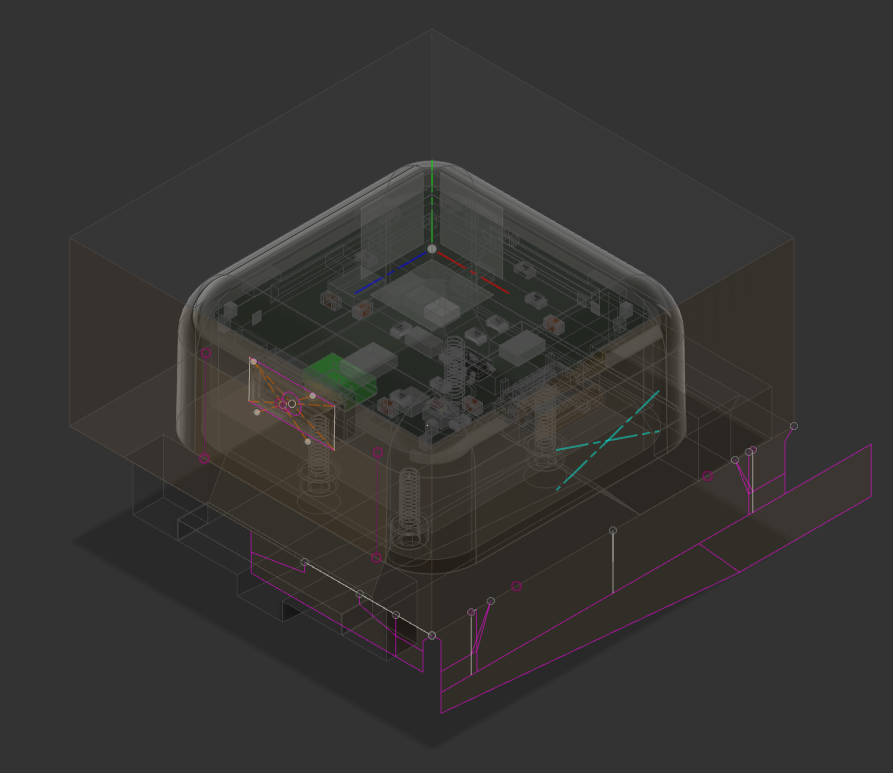

Smashlaps uses a 0.8mm thick PCB loaded with a LiPo charge controller, 290mAh LiPo battery, USB port for programming and battery charging, ATmega32u4 MCU due to its onboard USB interface and ease of integration, 3 high brightness 0603 LEDs, high efficiency LED driver, and a GreenPAK micro FPGA.

After the 2018 beta season, Dylan plans on migrating to an MSP430 MCU, optimizing the design, and reducing the product size.

The LEDs consume more than 95% of the system power; if it wasn't for them it would be able to run for months. As-is, the system runs for approximately 8 hours in a standard use case.

The Smashlaps housing is designed in Fusion360.

package design

The Smashlaps PCB and battery are encased in Simpact 65A polyurethane colored with white pigment. A 3D printed Polyjet mold is used to give the unit its shape, while a printed subcase holds the PCB and battery and is held in position by a 3D printed jig while the polyurethane cures.

The final product is entirely encased with the exception of the USB port. The bottom face of the printed subcase is exposed on the bottom of the unit; this allows for secure adhesion of the low profile 3M Dual-Lock that mates the unit to the rider's helmet.

A second-long button press turns the unit on or off; a quick button press signifies the rider's intent to start his run. The LEDs then flash in a traffic-light pattern, allowing for the rider to know exactly when to cross the start line.